[最も人気のある!] suspended slab formwork removal 205179

36—Inspection and adjustment of formwork 37—Removal of forms and supports 38—Shoring and reshoring of multistory structures backshores—shores placed snugly under a concrete slab suspended) and its supporting structure used for supporting workers, tools, and materials;Our offering includes engineering services, slab installations, formwork, in situ slabs, Echo rib & block slabs, concrete rib & block slabs, coffer slabs, concrete staircases & ready mix concrete We have enough equipment & formwork to handle the construction of any concrete slabs in Pretoria from 5 m² to 00 m² in one pour RESHORING CONCRETE SLAB AND BEAM We are reviewing a project where the contractor proposes to remove the forms and the associated shores for 9 bays (and fly the forms to the next level) before installing the reshores We expect that this might mean that at least some of the the slab and beams (ie those at the start of the form removal cycle

Top Down Approach Braces Half Of Subgrade Construction Concrete Construction Magazine

Suspended slab formwork removal

Suspended slab formwork removal- Removal Time Period Walls, columns and vertical sides of beams 24 to 48 hours as may be decidedA method of constructing a suspended floor is described in which a plurality of beamforming formwork assemblies are located in substantially parallel alignment, the beamforming formwork assemblies are supported in support assemblies on a support base in stable equilibrium, a plurality of floorforming formwork assemblies are located between the beamforming formwork

Period Of Removing Formwork For Beams Bottom Slab Bottom Youtube

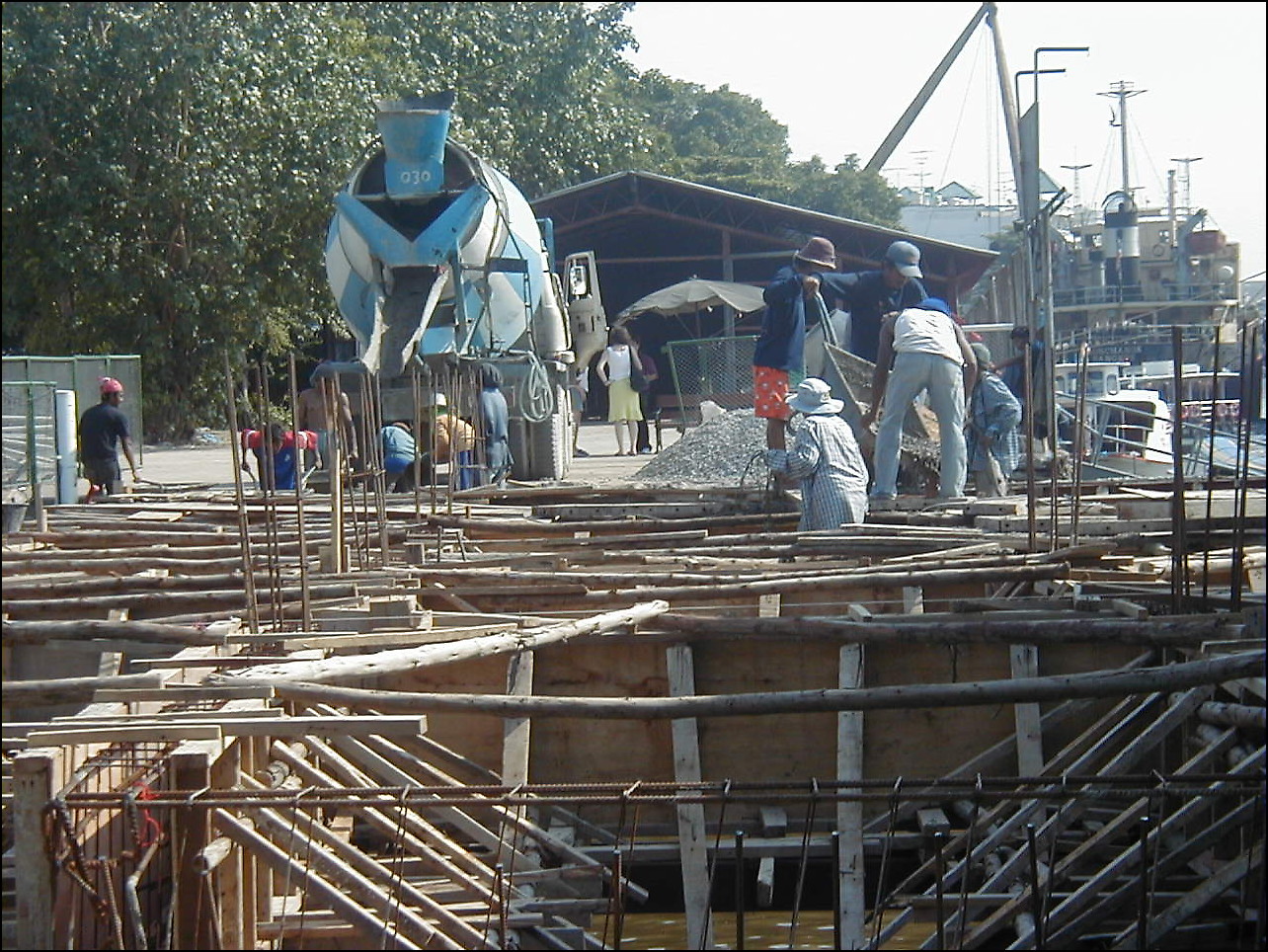

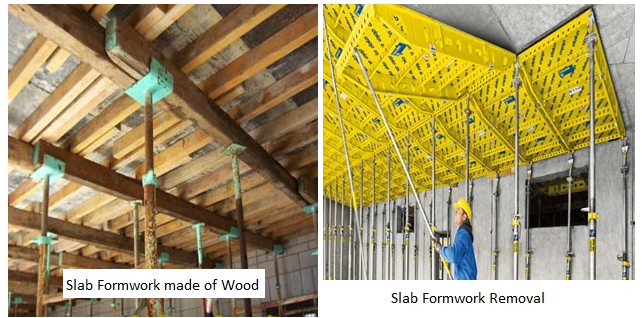

150mm reinforced concrete (124 30mm aggregate) base slab including formwork and its removal, levelling, compacting and curing 4 Sqm J Ditto 150mm thick suspended slab 4 Sqm K Reinforcement bars (10mm dia) Providing cutting bending Sawn formwork to the soffit of suspended slab 4 Sqm MThe selfweight of the completed concrete slabs is generally assumed in backpropping calculations to be based on a density of 24 kN/m³ for building multistorey flat slab structures When placing the new slab, the falsework and the backpropping should be designed for the new Formwork in construction is the use of support structures and moulds to create structures out of concrete which is poured into the moulds Formwork can be made using moulds out of steel, wood, aluminium and/or prefabricated forms Formwork is an ancillary construction, used as a mould for a structure Into this mould, fresh concrete is placed

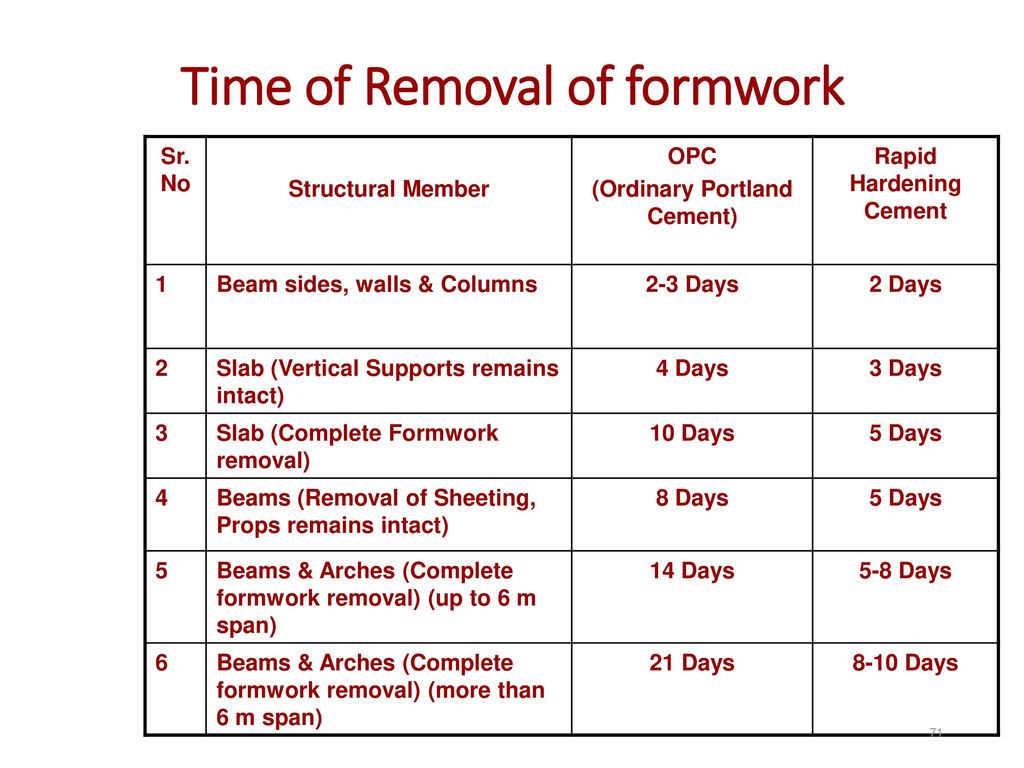

I am assuming 65m??Formdeck300 (FD300) is a very efficient and durable permanent metal tray formwork, reinforcement and ceiling system used for suspended concrete slab construction FD300 is an easy to use 300mm cover interlocking deck with deep swage pan stiffeners providing a strong fast and cost effective formwork solution It Is Ideal for exposed ceiling Shuttering removal time with Rapid hardening cement used Beam sides, walls and columns required 2 days Slab sides required 3 days Complete slab shuttering should be removed after 5 days Beams removal of sheeting required 5 days Beams and arches complete removal of shuttering required 5 to 8 days If beams and arches are of span more than 6

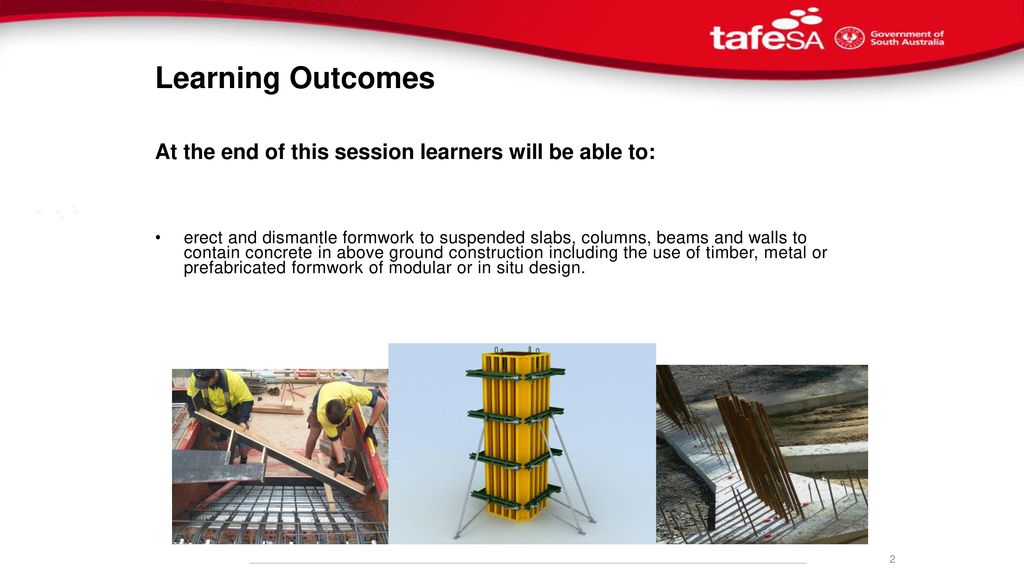

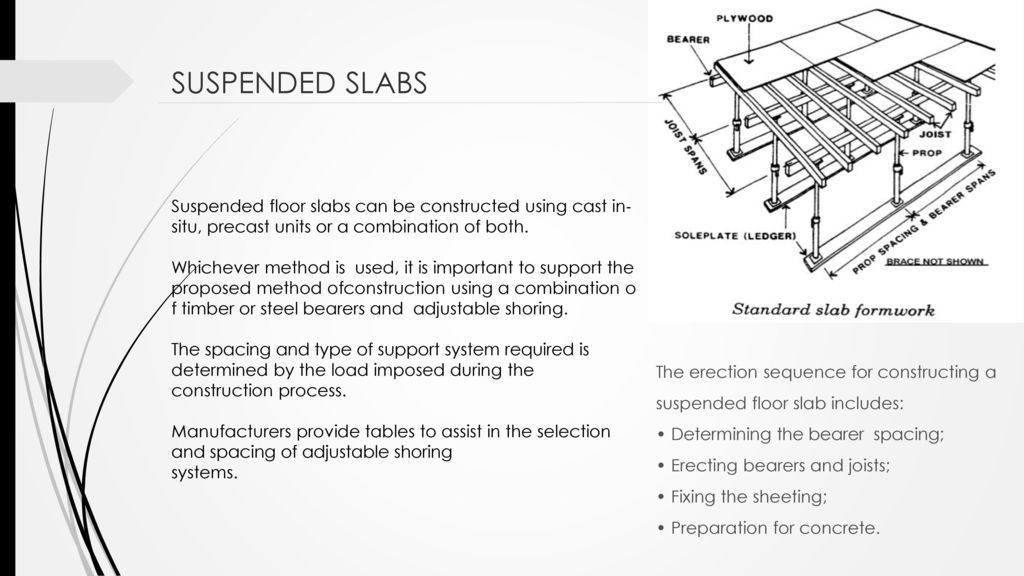

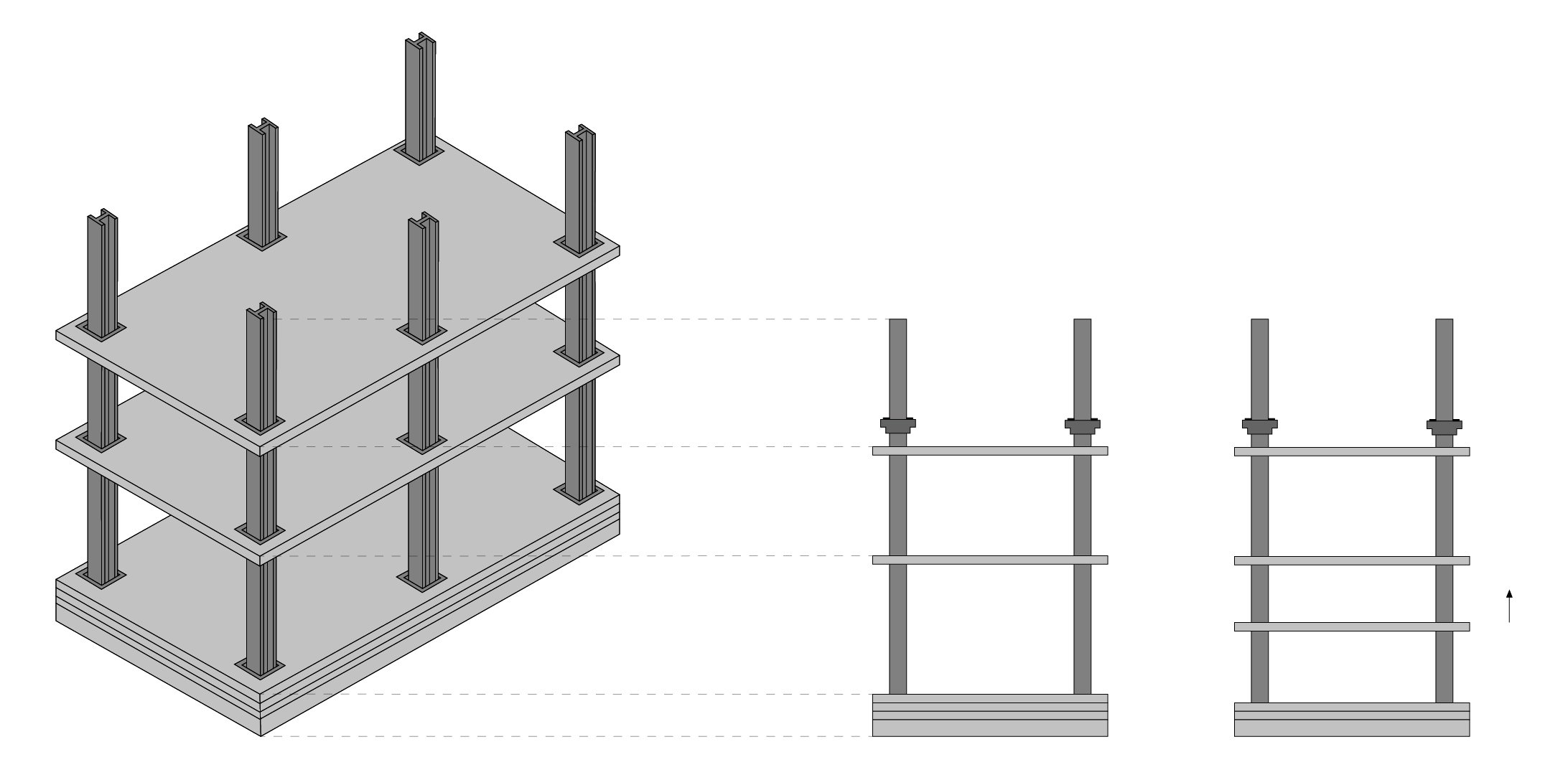

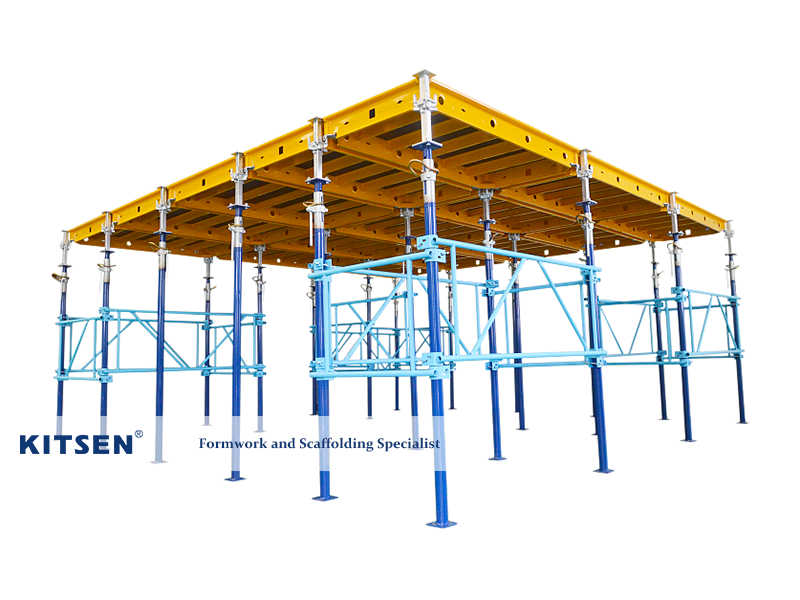

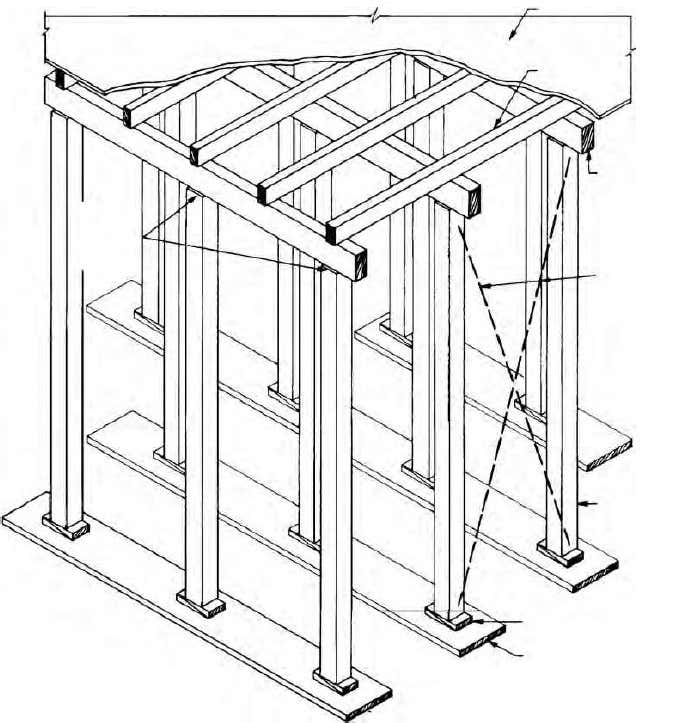

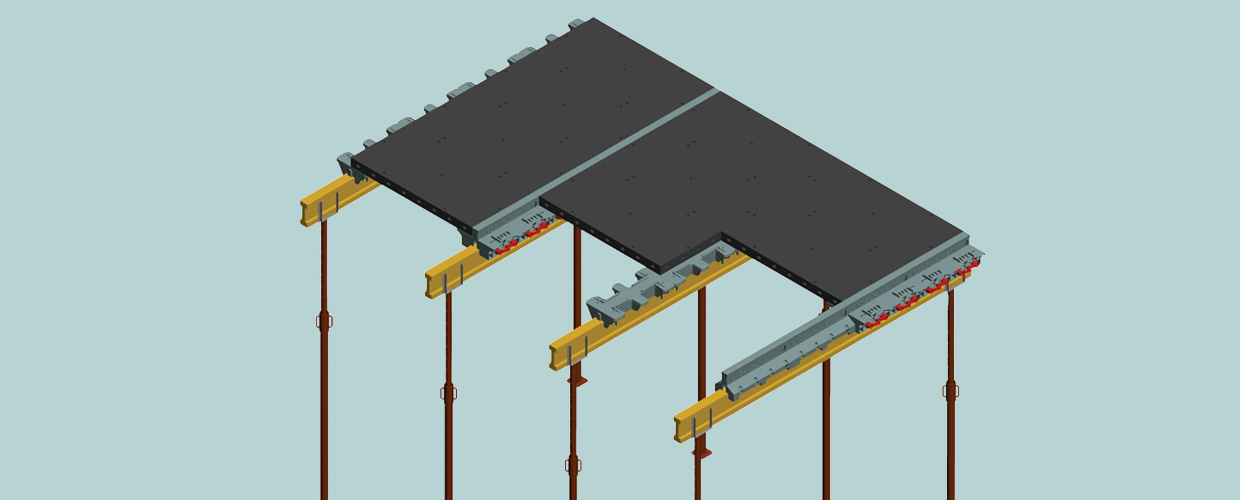

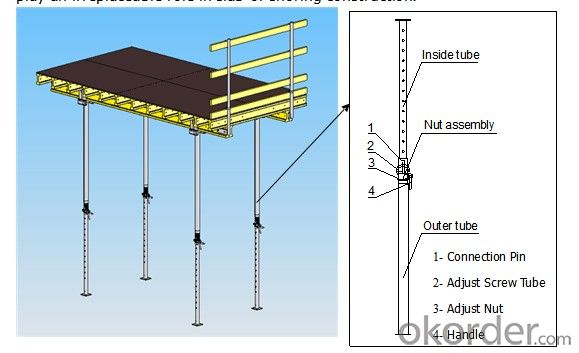

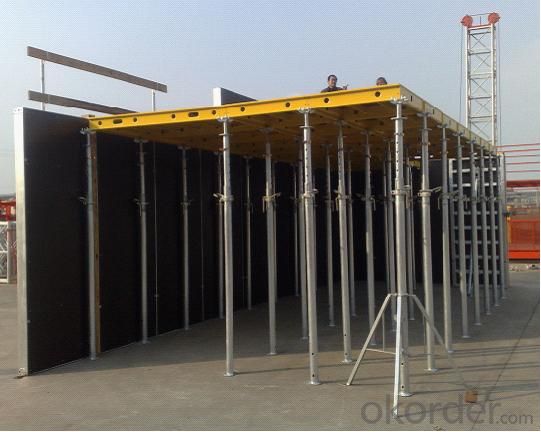

Column Formwork Construction To avoid plywood joints, it is normal practice to cut the sheets length wise in widths to match the column faces Most column forming methods use plywood to form faces The corner junctions of the plywood must be detailed to achieve the maximum tightening action from the column clampsThe Aluflex system is a high load capacity formwork system for the support and forming of suspended concrete slabs The systems basic components are the Alulight Multiprop, the Aluflex 105 Bracing Frame with primary and secondary beam options The primary beams being secured to the prop heads with steel clips or held in a steel fork head2 Erect formwork 21 Work area is cleared and surface prepared for safe erection of formwork for suspended slabs, piers and shutters 22 Formwork is set out to requirements of plans and specifications 23 Formwork is assembled to plans, specifications and class of surface finish , with support system set to correct height level and line

Method And Period Of Removing Formwork

When To Remove Concrete Forms How Long Should Concrete Cure Before Removing Forms Deshuttering Time Civiconcepts

Modulecon's Sure Slab System is a fully suspended concrete slab off ground solution designed for reactive soil conditions Through the ingenuity and collaboration of various patented building products, Modulecon has been able to resolve the major concerns regarding the management of soil conditions for domestic footing and foundation designsSuspended slabsFor a suspended slab, there are a number of designs to improve the strengthtoweight ratio In all cases the top surface remains flat, and th Suspended Floors All You Need To Know Thermohouse Formwork Requirements Types Materials Accessories Concrete Formwork Removal Time Specifications Hho Flexible Slab Formwork Systems Timber Beam Plywood Material S Hs Floor Connection Systems A Reinforced Concrete B Scientific Diagram

Quality Construction Of Suspended Floors Concrete Construction Magazine

Concrete Formwork Removal Time Specifications Happho

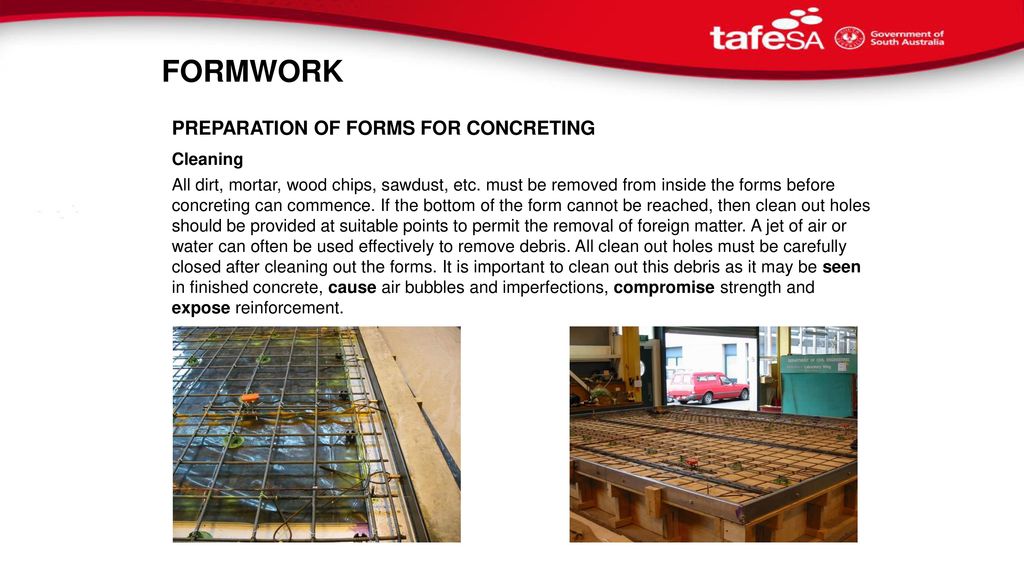

Removal of debris Provide all formwork with special cleanout holes to allow for the removal of sawdust, shavings, and other debris from the bottom of the formwork before the pour begins Formwork Tolerances and variations in alignment Columns Up toYes this is the span There are 5 of these 35m apart sitting on 400x400mm block posts Because it is suspended, are you using removal and integral form?Removal Release Dropheads with a hammer These quickrelease Dropheads allow for removal of framing members as early as one day after the pour in accordance with ACI 301 section 2325 Remove Main Beams and Secondary Beams and place them in the barellas These beams can be cycled to floors above, requiring less equipment overall

Formwork For Civil Engineering Construction Works Ppt Video Online Download

Safety Concrete Formwork For Suspended Slabs China Slab Formwork Aluminum Shutter Made In China Com

Chapter 4—Strength adequacy of concrete slabs and formwork, p 3472R8 41—Earlyage concrete material strength development 42—Construction load factors 43—Earlyage capacity of concrete slabs 44—Serviceability requirements 45—Formwork adequacy Chapter 5—Construction examples, p 3472R10 51—Twoway slab constructionStep 4 Pull the forms away from the sides of the concrete slab using as little force as necessary If a form sticks to the slab or is difficult to remove, use the pry bar to pry the form upward from the ground, loosening the form from the concrete in the process PullPropping on suspended slabs and beams, ground movement under slabs cast on ground, shrinkage and curling effects etc) In the case of columns and walls, measurement should take place as soon as is possible after formwork removal MEASURING TOLERANCES As the specification of tolerances is dependent on the method of measurement, this is usually

Cornerstone Building Civil Engineering Suspended Slab With Removable Formwork Ready For Concrete Pouring Looking At The Example In The Image The Steel Bars Are There To Withstand And Counteract The

Concrete Formwork For Slabs

Strike reinforced concrete slabs in two stages 1 Ease all the supports 2 Starting at midspan, remove supports working towards columns and walls Posttensioned slabs will tend to lift off the formwork on tensioning, but use method for rc above On large slab areas, comprising internal and edge panels, strike internal Engineered formwork is a type of mold that concrete is poured into to create walls, slabs, columns, and many other types of cement structures Engineered formwork is a metal mold, typically made of steel or aluminum, gives contractors the option to create structures of many different shapes and sizes It is a costeffective alternative to I mean that the slab isn't associated with our existing residence What is the span?

An Essential Guide To Concrete Formwork Removal Giatec Scientific

Column Formwork Procedure Formwork For Slabs And Beams

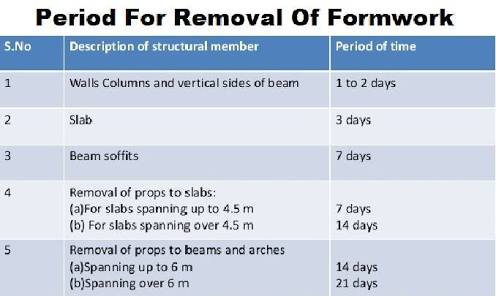

6 rows Time of Removal 1 Walls, columns and vertical sides of beam 2448 hours 2 Slabs ( propsABSTR4CT Andysis of Construction Loads on Concrete Fomwork Basher Aiamin This study presents analytical procedures for determining the loads on the shoring system and supportïng slabs during the construction of multistory concrete buildings and for determining the lateral pressures imposed by fksh concrete against the walI fonns TheBased on this strength criteria, the minimum period required for removal of formwork for slabs, in normal conditions where the prevailing temperatu Suspended concrete slabs are generally constructed in two ways Precast The slab is constructed in forms elsewhere;

Garagedeck The Flexible Formwork Solution For Beam Peri Usa Manualzz

How To De Shutter The Slab Of A High Rise Building

Factory Price Wholesale Wall Suspended Slab Black Pp Plastic Construction Formwork , Find Complete Details about Factory Price Wholesale Wall Suspended Slab Black Pp Plastic Construction Formwork,Formwork Wall,Suspended Slab Formwork,Black Pp Plastic Construction Formwork from Formwork Supplier or ManufacturerShandong Green Plastic Co, LtdIf you are making say 50mm thick wedges for formwork use a bit of 150 x 50 for your jigCut a length of say 150 x 50 hardwood into 250 long lengths After the first wedge is cut flip the material length wise to cut the next wedge and so onRemoval of formwork before the concrete achieves adequate strength overloading of the formwork during concrete pouring operations Formwork can be constructed to meet a custom design produced by a competent person or a proprietary system can be used in accordance with the manufacturer's recommendations

Adjustable Prop Vertical Robust Suspended Slab Formwork System Real Time Quotes Last Sale Prices Okorder Com

Concrete Formwork Removal Time Specifications And Calculations The Constructor

Slab formwork is used to construct a suspended concrete slab that is not directly supported by the ground It acts as a mold in which fresh concrete can be poured in so that it can get a desired shape and size When a slab is suspended, the formwork's job is to support the concrete of the slab till it is perfectly curedDetail_080 Concrete filled Rapidwall with RW slab formwork ceilingPeriod For Formwork Removal For rapid hardening cement 3/7th of the periods given in the above table will be sufficient in all cases except vertical sides of slabs, beams, and columns which should be retained for at least one day All formwork should be eased gradually and carefully in order to prevent the load from being suddenly transferredTrue Form formwork range encompasses many services such as supply, erection, dismantle, and removal of formwork We also provide you with many other formwork services including suspended slabs, roughed slabs (Slab on ground/ raft slab), stairs (spiral, straight flight, wider stairs), waffle boards, retaining walls, dincel walls, beams, lift

Formwork Wikipedia

Formwork Cpccca3019a Erect Dismantle Formwork For Suspended Slabs Columns Beams And Walls Ppt Download

Place two frames R150 on the supporting timbers Wind the quick jack nut on the spindle, bolt the base plate with pins and cotter pins onto the spindle, and push the four base spindles into the bottom side of the vertical tubes of the frames Insert two base spindles with a reinforcing support into the frame tubesAdjustable metal scaffolding can Typically loosened at 1 day and supported with formwork being removed at 3 days and reshored for 14 days Else you get added deflections and or cracking If you don't loosen the formwork, it can get 'glued' to the concrete Dik

1

Structure Suspended Slab Home Building In Vancouver

Quick and easy slab solution No excavation or soil removal No need for heavy machinery No need to strip formwork after pour Lower cost, especially on reactive soil sites Determine accurate concrete volumes and minimize wastage Pure suspended slab with no environmental disturbance Fully engineered and certified in Australia, meeting allPractical activity for Illawarra Carpentry Students to complete formwork to suspended slabs beams and columnsUNIT DESCRIPTOR CPCCCA3019A Erect and dismantle formwork to suspended slabs, columns, beams and walls This unit of competency specifies the outcomes required to erect and dismantle formwork to suspended slabs, columns, beams and walls to contain concrete in

How To Prevent Concrete Formwork From Failing

When To Remove Concrete Formwork Civilblog Org

Doka is a world leader in providing innovative formwork, solutions and services in all areas of construction The company is also a global supplier of wellthoughtout scaffolding solutions for a varied spectrum of applications With more than 160 sales and logistics facilities in over 60 countries, Doka has a highperforming distribution network for advice, customer service and 10 days** 7 days * But observe requirements for floor slabs or soffits of joists and beams, if the same forms support them** Half this interval if forms may be removed without disturbing shores*** 3 days if forms may be removed without disturbing shoresThe present invention relates to a formwork arrangement for forming a suspended concrete floor slab comprising a change in level in an underside thereof, a support bracket for use with such a formwork arrangement, and a method for employing the support bracket and formwork

Formwork Removal Of Slab Embedded Beams Structural Engineering General Discussion Eng Tips

Concrete Formwork Removal Time Specifications Happho

Efficiently using your formwork can lead to a significant reduction in the amount you need to purchase Follow this guide to determine you concrete form necessities and begin saving on your next project For your next concrete project, contact Forming America or call 1For suspended slabs, the formwork will be in the shape of a tray, with supporting slabs underneath After the concrete sets the formwork and supports are removed Suspended S labs Are Widely Used In The Construction Industry Due to it's many advantages it speeds up construction as well as saves on costsI would imagine that the formwork stays in place – whatever is cheapest for this

An Essential Guide To Concrete Formwork Removal Giatec Scientific

Analysis Of The Construction Of A Reinforced Concrete Free Form Roof Formwork And The Development Of A Unit Construction Method Sciencedirect

Once completed and cured it is put in place by cranes or jacks, then(A) Removal of Slab Shuttering If the Cement used for slab concrete is OPC 33grade ( ISI269 ), OPC 43grade ( ISI8112 ) & PPC Cement ( ISI14 ) Supports in the area where the distance / width of room from beam to beam ( wall to wall ) is less than 36m , can be removed after 11daysFormwork that supports horizontal surfaces is called centering Example formwork for the floor, floor beam bottom, slab, etc It is a type of formwork that support only horizontal surface In the below image you can see the centring work for slab

Top Down Approach Braces Half Of Subgrade Construction Concrete Construction Magazine

Ring Lock Scaffolding Table Formwork Real Time Quotes Last Sale Prices Okorder Com

FORMWORK Health and Safety Construction Safety Association of Ontario 21 Voyager Court South, Etobicoke, Ontario M9W 5M7 Canada (416) Fax (416) Allow the concrete to dry before removing the forms Remove forms starting at the top of sloping slabs Remove the stakes from the ground that support the forms with a stake puller to avoid damaging the stakes or the forms Pull the forms away from the sides of the concrete slab using as little force as necessary

1

Removal Of Formwork Know The Correct Time And The Precautions

Concrete Formwork Alternatives For Construction Pros

Formwork Ppt Download

Period Of Removing Formwork For Beams Bottom Slab Bottom Youtube

De Shuttering Period Of Formwork Concrete Formwork Removal Time Youtube

Www Ihsa Ca Pdfs Products Id M064 Pdf

S3 Amazonaws Com Suncam Docs 2 Pdf

Formwork Cpccca3019a Erect Dismantle Formwork For Suspended Slabs Columns Beams And Walls Ppt Download

Adjustable Prop Vertical Robust Suspended Slab Formwork System Real Time Quotes Last Sale Prices Okorder Com

1

4 1 Formwork For Concrete Slab

Formwork Wikipedia

China Table Formwork Will Be Quickly Removed By Shiftng Trolley In Slab Construction Slab Formwork System

Slab Formwork Early Stripping Slab Formwork Systems Kitsen

Lift Slab Construction Wikipedia

/concreting-formwork-for-the-foundation-857756224-5b7ed9cdc9e77c00573a1357.jpg)

Safety Installation And Removal Of Formwork

Architectural Aluminum Formwork System If Formwork System Kitsen Fastform

Formwork Stripping In Progress Youtube

Formwork

Slab Formwork Early Stripping Slab Formwork Systems Kitsen

When To Remove Concrete Forms How Long Should Concrete Cure Before Removing Forms Deshuttering Time Civiconcepts

Formwork For Decks And Floors Concrete Construction Magazine

When To Remove Concrete Formwork Civilblog Org

Deshuttering Time When To Remove Concrete Forms Concrete Formwork Removal Time Earliest Time To Remove Concrete Forms When To Strip Concrete Forms

Modular Formwork E Deck Paschal Werk G Maier Gmbh Slab Beam

4 1 Formwork For Concrete Slab

Commercial Formwork Unitec

Concrete Formwork Removal Time Specifications And Calculations The Constructor

Things To Check Before Concreting Beams Slabs

An Essential Guide To Concrete Formwork Removal Giatec Scientific

Slab Formwork Dokadek 30 Doka

Formwork Stripping Time For Different Structural Elements

Concrete Formwork For Slabs

Formwork Wikipedia

Concrete Floor Slab Construction Process The Constructor

How Long Should You Wait To Remove Concrete Formwork Eiffel Trading

Preventing Concrete Formwork Failures In The Commercial Construction Process

Concrete Formwork For Slabs

Suspended Slab Formwork Cassaform Construction Systems

Removal Of Formwork Know The Correct Time And The Precautions

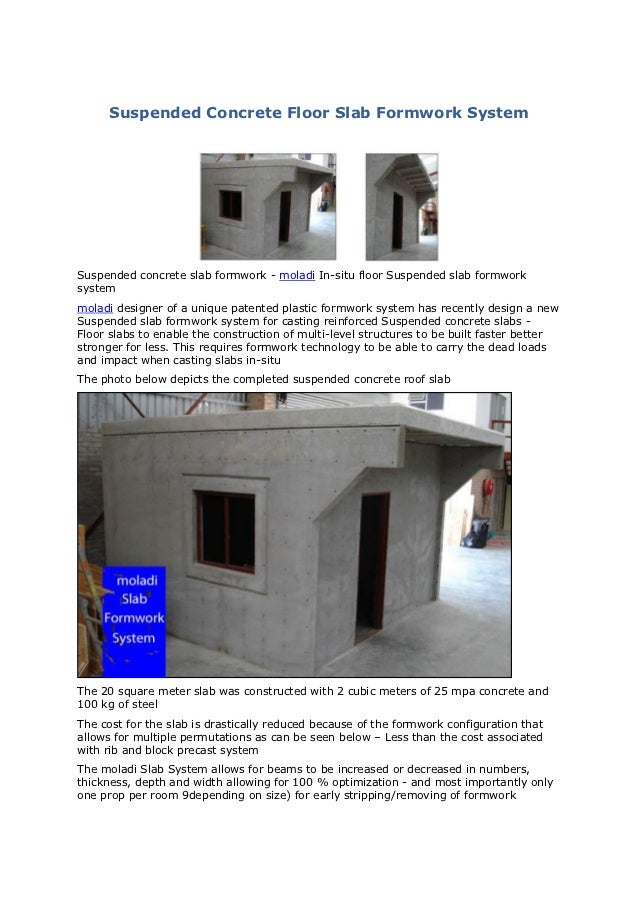

Suspended Concrete Floor Slab Formwork System

Concrete Floor Slab Construction Process Eplan House

Concrete Formwork For Slabs

Geosky Geoplast

Panel Floor Formwork Dokadek 30 With Drop Head Doka Lietuva

What Is The Minimum Number Of Days To Dismantle Formwork In A Reinforced Concrete Slab Quora

File Slab Formwork Tables Jpg Wikimedia Commons

1

Concrete Formwork Alternatives For Construction Pros

Method And Period Of Removing Formwork

Expanded Polystyrene Eps Formwork Block Zlabform Zego Pty Ltd For Flooring Concrete Floor Slab Insulating

Concrete Formwork Removal Time Specifications Fantasticeng

What Is The Minimum Number Of Days To Dismantle Formwork In A Reinforced Concrete Slab Quora

Why Wouldn T You Use Modular Slab Formwork Systems

Removal Of Formwork Formwork Removal Time Formwork Deshuttering

Types Of Formwork For Concrete Structures

Adjustable Prop Vertical Robust Suspended Slab Formwork System Real Time Quotes Last Sale Prices Okorder Com

Measurement Of Concrete Formworks For Payment Calculation

How Many Days Can The Formwork Be Removed During Construction Bofu Formwork

Deshuttering Time When To Remove Concrete Forms Concrete Formwork Removal Time Earliest Time To Remove Concrete Forms When To Strip Concrete Forms

Formwork Cpccca3019a Erect Dismantle Formwork For Suspended Slabs Columns Beams And Walls Ppt Download

What Is The Minimum Number Of Days To Dismantle Formwork In A Reinforced Concrete Slab Quora

Concrete Slab Wikiwand

Concrete Slab Wikidwelling Fandom

Shuttering Removal Time Formwork Stripping When To Remove Scaffolding Youtube

Method Statement For Erection And Dismantling Of Slab Formwork Project Management 123

Concrete Slab Wikipedia

Residential Extension Project Seven Hills

Formdeck Fd300 Durable Permanent Metal Tray Formwork Reinforcement System For Suspended Concrete Slab Construction

Shuttering Removal Time Of Different Structural Members

What Are Formwork Shuttering Centering Staging And Scaffolding

Adjustable Prop Vertical Robust Suspended Slab Formwork System Real Time Quotes Last Sale Prices Okorder Com

Large Area Formwork Top 50 By Acrownz Issuu

Formwork Cpccca3019a Erect Dismantle Formwork For Suspended Slabs Columns Beams And Walls Ppt Download

How When To Remove Formwork Hipages Com Au

Ground Beam And Suspended Slab Formwork Work Process Traditional Timber Formwork Shuttering Works Youtube

Removal Of Timber Supports At Suspended Slab House Construction Youtube

コメント

コメントを投稿